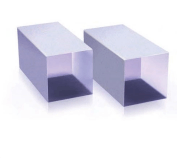

Say Goodbye to Gray Tracking with Hydrothermally Grown KTP Crystals

Potassium Niobate (KTP) is a versatile and crucial material in many different fields and applications, including high-power laser systems, optical frequency conversion, and skin resurfacing treatments. The quality and performance of KTP crystals are dependent on the growth method used to produce them.

While other growth methods, such as top seeded solution growth, may produce KTP crystals, they often result in lower quality crystals with more defects and impurities. This can lead to issues such as gray tracking in high-power laser systems, where small cracks or damage to the KTP crystal can cause the laser light to scatter, reducing the efficiency and performance of the laser.

On the other hand, Hydrothermal growth is a highly effective solution growth method for producing high quality KTP crystals. This method allows for the growth of large, high-quality KTP crystals with minimal defects, reducing the risk of gray tracking in high-power laser systems. Furthermore, the large size of the crystals produced through hydrothermal growth allows for more efficient site selection, reducing thermal stress on the crystal and improving its performance.

Selection of Materials

The selection of the right materials is critical for the performance and efficiency of a laser system. At Davis Marketing International, we use whole boule interferometry to ensure that we select the highest quality KTP crystals. This process allows us to measure the optical properties of the crystal and identify any defects or impurities, ensuring that our clients receive only the best materials for their laser systems.

Finishing and Coating

In addition to selecting the right materials, the finishing and coating of the KTP crystal can also impact its performance and efficiency. At Davis Marketing International, we take great care to ensure that our KTP crystals are finished and coated to the highest standards. Our expert technicians use the latest techniques and technologies to provide the best results for our clients.

The Benefits of Hydrothermally Grown KTP Crystals

Hydrothermal growth is a proven solution growth method for producing the highest quality KTP crystals. This method has many advantages over traditional crystal growth techniques, making it the preferred method for producing KTP crystals for high-power laser systems.

One of the key benefits of hydrothermally grown KTP crystals is their large size and high quality. This growth method allows for the production of KTP crystals with minimal defects, reducing the risk of gray tracking in high-power laser systems. This is because hydrothermal growth allows for a controlled environment, with precise control over temperature and pressure, resulting in the production of large, high-quality KTP crystals.

In addition, hydrothermally grown KTP crystals have a homogenous structure, with no visible cracks or inclusions. This results in improved performance and reliability, making hydrothermally grown KTP crystals the ideal choice for high-power laser systems.

The Importance of High Quality KTP Crystals

Having high quality KTP crystals is crucial for the performance and efficiency of a laser system. Poor quality materials can lead to issues such as gray tracking, where small cracks or damage to the KTP crystal can cause the laser light to scatter, reducing the efficiency and performance of the laser. At Davis Marketing International, we are committed to providing only the highest quality materials to ensure that our clients receive the best results.

Contact Us To Buy Hydrothermal Grown KTP

Don't settle for lower quality KTP crystals. Choose the best with Hydrothermally Grown KTP from Davis Marketing International. Contact us today at (866) 456-1064 or visit our KTP page to learn more about how we can help you achieve the best results for your laser systems.

Contact Us To Discuss Your Application:

Davis Marketing International features YAG from Laser Materials Corporation and VANADATE materials from the highest quality in the Pacific Rim.

Explore

Services

© 2021 | All Rights Reserved | Davis Marketing International | Privacy Terms & Conditions